American Standard Teardrop Pallet Rack

Contact us for a free consultation or to place a custom order.

Product Introduction

The Teardrop Pallet Rack provides direct access to each pallet, simplifying inventory management and offering versatility. The upright frame serves as a crucial element of the pallet rack structure. BHD offers upright frame columns in various sizes and thicknesses, providing a diverse range of load-carrying capacities to suit your specific needs and applications. The teardrop beam-to-column connection from BHD is designed to seamlessly integrate with other widely available teardrop systems.

KEY FEATURES

- Teardrop Design: The iconic teardrop-shaped holes on the uprights allow for tool-free beam installation. This means quicker setup, lower labor costs, and the flexibility to change beam levels with minimal effort.

- High Strength & Load Capacity: Manufactured using industrial-grade steel and precise roll-forming, the system is designed to handle heavy-duty loads while maintaining structural integrity over time.

- Fast Installation: Beams securely lock into place using sping lock or spring pins — no bolts or complicated fittings required.

- Durable Finish: Powder-coated surface ensures corrosion resistance, longevity, and a clean appearance in demanding environments.

- Custom Configurations: Can be tailored to specific height, depth, and load requirements.

MAIN COMPONENTS

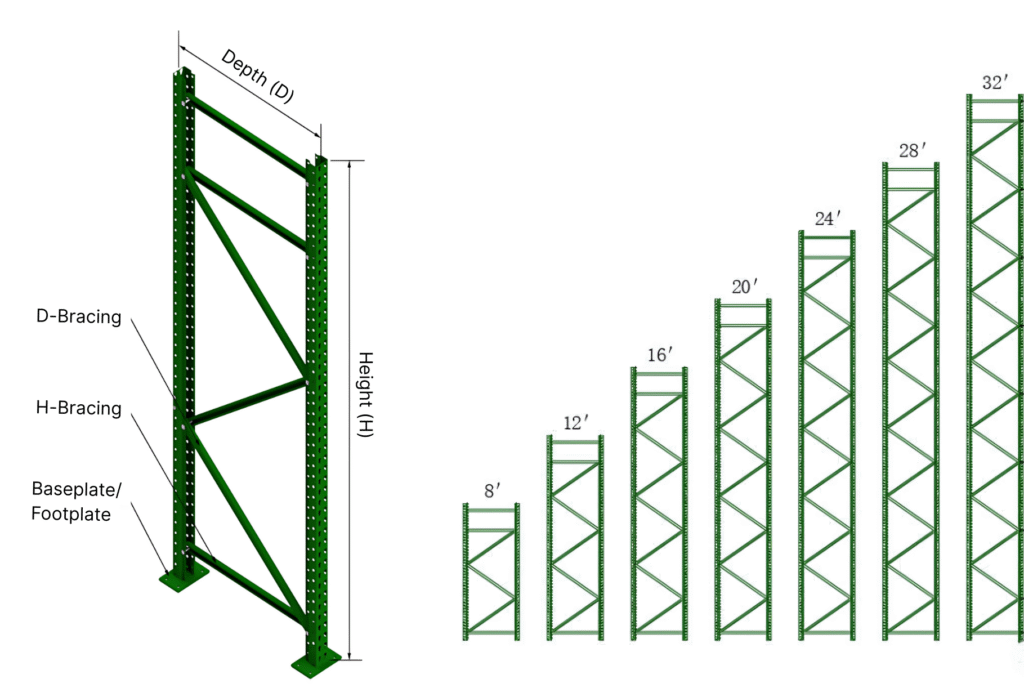

BOLTED-TYPE FRAME

Composition: The frame consists of uprights, horizontal and diagonal bracings, bolts, spacers, and baseplates (either welded or bolted types). Standard depths are 36″, 42″, and 48″.

Features: Bracings are connected to the uprights using special bolts and assembled on-site into a full frame. The components are compactly packed for easy transportation and are less likely to be damaged during transit.

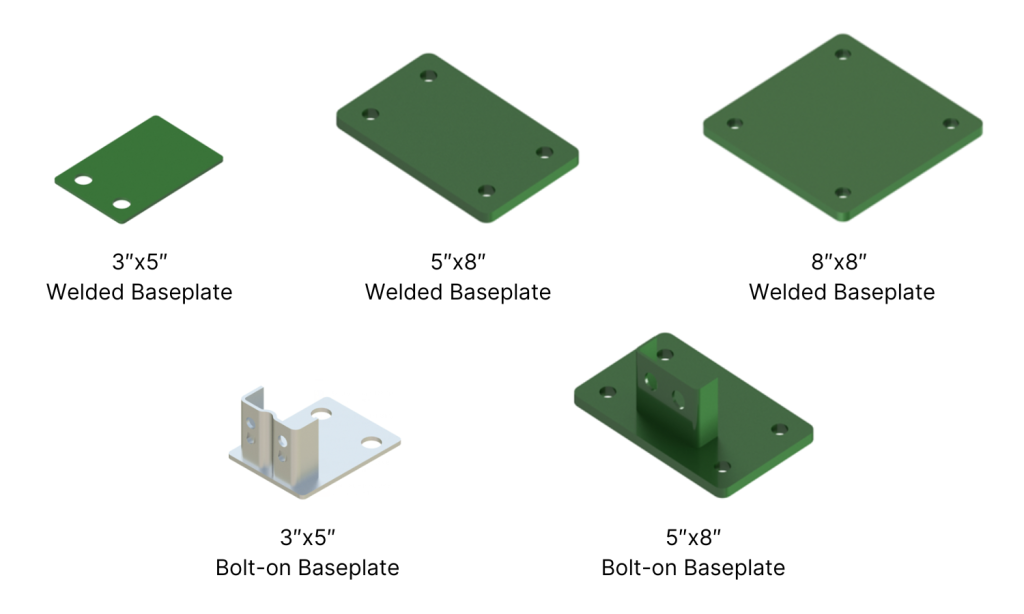

The baseplate anchors the upright to the floor, ensuring stability and load distribution. Available in welded or bolted types for different installation needs.

| Frame Loading Capacity (Lbs) | ||||

| First Beam Level | 3″×3″×14Ga (1.9mm) | 3″×3″×13Ga (2.3mm) | 3″×3″×12Ga (2.5mm) | |

| (mm) | (inch) | |||

| 1219.2 | 48 | 21,780 | 26,180 | 28,380 |

STEP BEAM

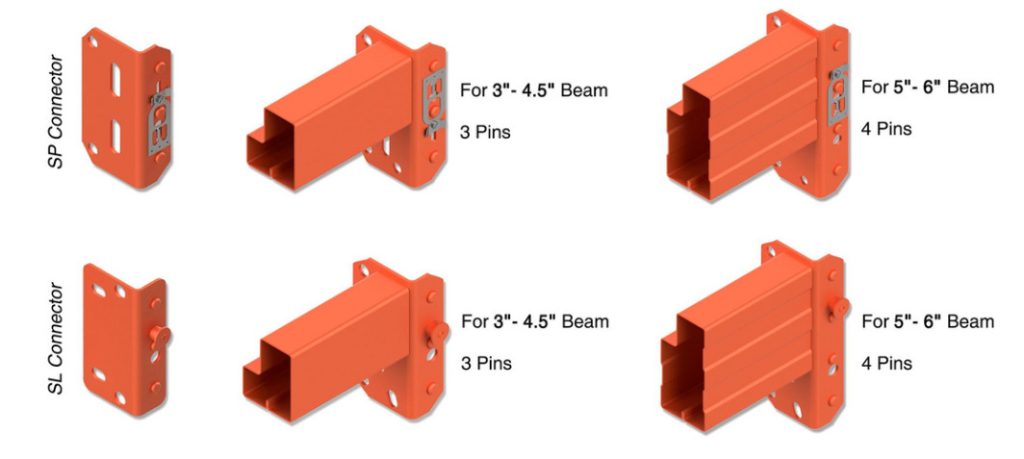

Composition: Made of an integrated P-type step beam with rivet-style brackets welded at both ends.

Length: Standard lengths are 96″, 108″, 120″, and 144″, with a tolerance of ±0.5mm.

Common Sizes:

- 96″×3″×16GA (1,986 Lbs)

- 96″×4″×16GA (4,027 Lbs)

- 96″×4.5″×16GA (5,216 Lbs)

- 144″×5″×16GA (3,173 Lbs)

- 144″×6″×14GA (6,337 Lbs)

Safety Feature: Brackets are equipped with SP or SL safety pins to ensure secure connection between beam and upright.

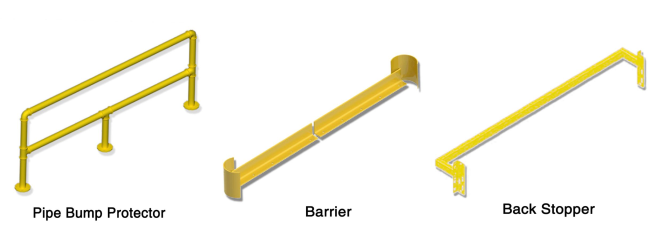

RACK ACCESSORIES

SYSTEM OPTIONS

- Height, Depth, and Width: Fully customizable based on warehouse layout and loading needs.

- Surface Finish: Standard powder-coated finish/Galvanized

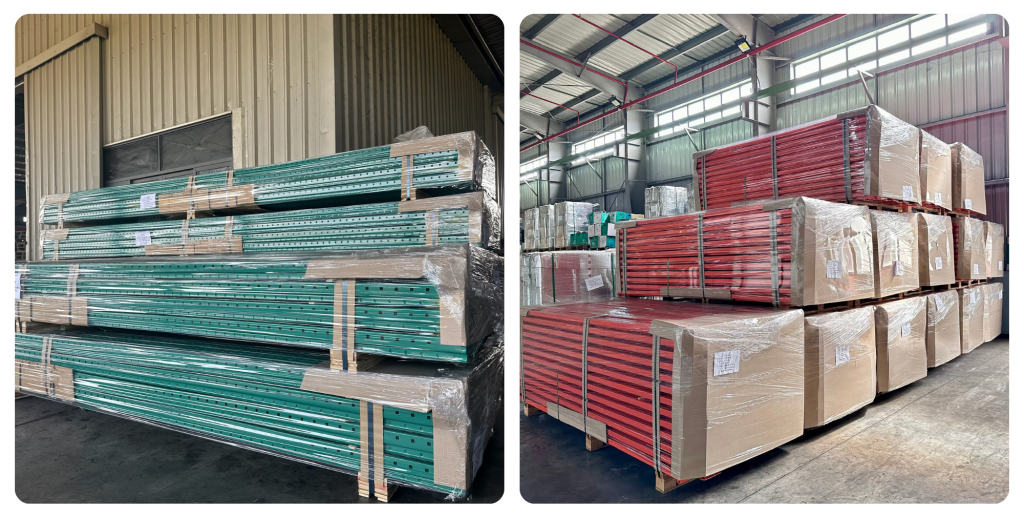

PACKAGING & LOADING

Our packaging and loading process is carefully crafted to ensure every product arrives safely, securely, and ready for installation.

Our Packaging Materials Include:

- Corrugated Paper

- Carton Boxes

- Crossties & Pallets

- Angle Steel

- Plastic Film

- Steel Ties

- Airbags

Our commitment to professional packaging skills goes beyond merely ensuring safe delivery; it also serves to streamline processes, saving time and minimizing the risk of damage during loading and unloading operations.

WHY CHOOSE BHD VIETNAM RACKING FACTORY?

- Experienced Manufacturer – Serving international markets with years of racking expertise.

- Global Reach – With factories in Vietnam and warehouses in the U.S. and Australia, we support fast and reliable shipments worldwide.

- Reliable Partner – We build long-term partnerships through dependable service, custom solutions, and consistent product quality.

- Export-Focused – We specialize in manufacturing for export, with a deep understanding of logistics, container optimization, and global compliance.

Other products

Australian Standard Heavy-duty Pallet Rack

Cantilever Rack

Wire Mesh Decking

60 Longspan Shelving