Australian Standard Heavy-duty Pallet Rack

Contact us for a free consultation or to place a custom order.

Product Introduction

The Australian Standard Heavy-Duty Pallet Rack is specifically engineered to meet the stringent requirements of AS 4084-2012, ensuring outstanding safety, stability, and load-bearing capacity for demanding industrial environments. Built for high-capacity warehousing, manufacturing facilities, and logistics hubs, this system delivers uncompromising performance in both static and dynamic storage operations. Its robust construction and compatibility with local standards make it a trusted choice across Australia and New Zealand, where it is widely adopted for its reliability, ease of installation, and long-term durability.

KEY FEATURES

- AS 4084-2012 Compliant: Fully engineered to conform with Australia’s national racking standard, guaranteeing long-term structural integrity and workplace safety.

- High Load Tolerance: Supports up to 4,000 kg per beam level, making it ideal for storing heavy pallets and bulky goods.

- Industrial-Grade Steel Construction: Cold-formed frames and box beams ensure exceptional strength and durability.

- Corrosion-Resistant Coating: Durable powder coating or hot-dip galvanizing options protect against wear, moisture, and environmental exposure.

- Flexible Configurations: Available in multiple sizes and layouts to suit various floor plans, storage heights, and pallet types.

MAIN COMPONENTS

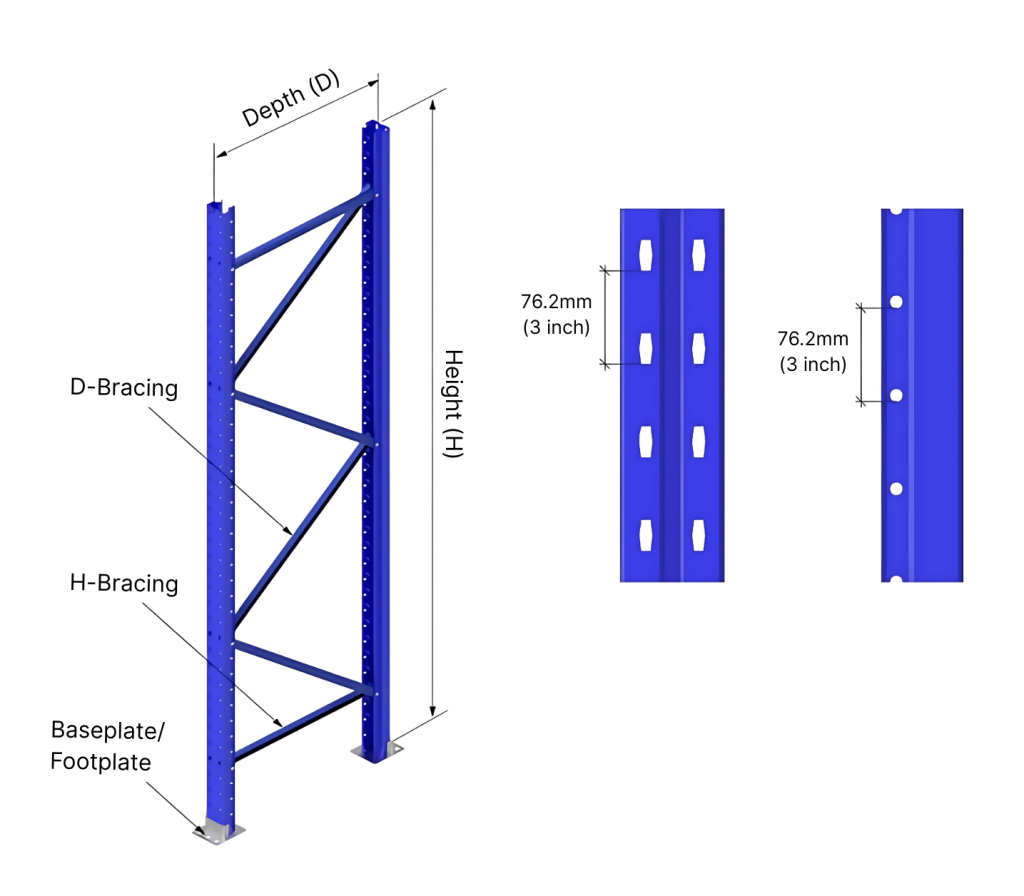

FRAME

Composition: The frame consists of uprights, horizontal and diagonal bracings, bolts, spacers, and baseplates. Standard depths are 838.2 mm, 914.4mm, 1000mm, 1066.8 mm, 1100mm, 1219.2 mm.

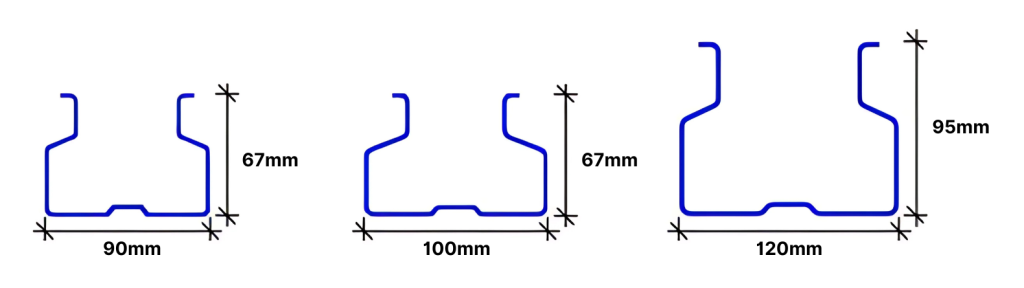

Standard Cross-Section Dimensions (mm):

- 90 x 67 x 1.8/2.0/2.3

- 100 x 67 x 2.0/2.3/2.5

- 120 x 95 x 2.5/2.75/3.0

The baseplate ensures the column remains stable, distributes its load evenly across the floor, and anchors it firmly to the ground for reliable structural support. The baseplate comes in four types: Stamping Baseplate, Single-Row Hole Baseplate, Double-Row Hole Baseplate, and Three-Row Hole Baseplate. Each type is designed to provide varying levels of support and load distribution.

| Frame Loading Capacity (Tons) | |||

| First Beam Level (m) | Column Specifications | ||

| 90 x 67 x 1.8 (AS90S) | 90 x 67 x 2.0 (AS90U) | 90 x 67 x 2.3 (AS90H) | |

| 1.0 | 8.4 | 13 | 15 |

| 1.4 | 8.4 | 11.8 | 13.8 |

| 1.8 | 8.4 | 10.6 | 12.6 |

| 2.0 | 7.8 | 10 | 12 |

| 2.2 | 7.2 | 9.4 | 11.4 |

| 2.4 | 6.6 | 8.8 | 10.4 |

| 2.6 | 6 | 8.2 | 10.2 |

| First Beam Level (m) | Column Specifications | ||

| 100 x 67 x 2.0 (AS100S) | 100 x 67 x 2.3 (AS100U) | 100 x 67 x 2.5 (AS100H) | |

| 1.0 | 14.4 | 16.4 | 18.4 |

| 1.4 | 13.2 | 15.2 | 17.2 |

| 1.8 | 12 | 14 | 16 |

| 2.0 | 11.4 | 13.4 | 15.3 |

| 2.2 | 10.8 | 12.8 | 14.6 |

| 2.4 | 10.2 | 12.2 | 13.9 |

| 2.6 | 9.6 | 11.6 | 13.2 |

| First Beam Level (m) | Column Specifications | ||

| 120 x 95 x 2.5 (AS120S) | 120 x 95 x 2.75 (AS120U) | 120 x 95 x 3.0 (AS120H) | |

| 1.0 | 20.8 | 24 | 27 |

| 1.4 | 19.4 | 22.5 | 25.5 |

| 1.8 | 18 | 21 | 24 |

| 2.0 | 17.3 | 20.2 | 23.2 |

| 2.2 | 16.6 | 19.4 | 22.4 |

| 2.4 | 15.9 | 18.6 | 21.6 |

| 2.6 | 15.2 | 17.8 | 20.8 |

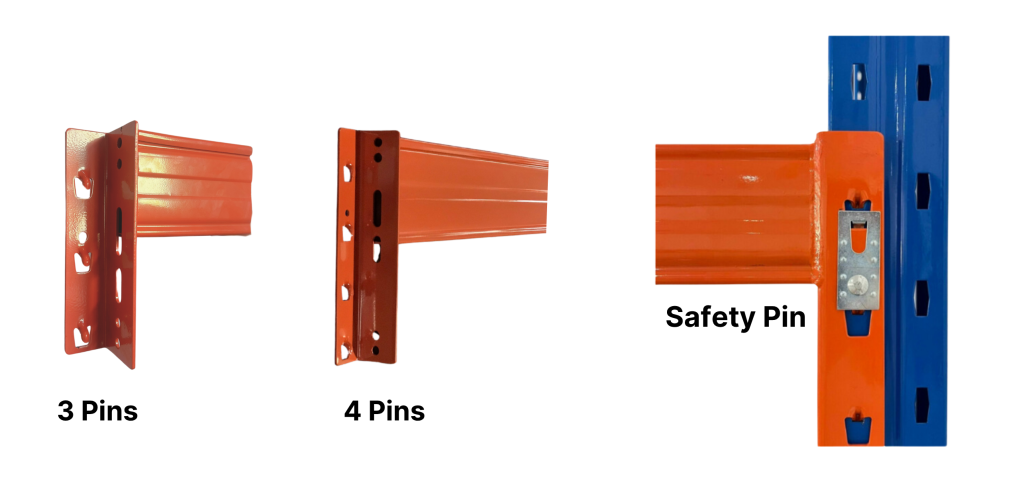

BOX BEAM

Composition: The standard beam consists of rolled interlocking beams with column clips welded at both ends of the beam. Depending on the structure’s requirements, welded pipes or other profiles may also be used as the beam.

Length: The standard length L is the dimension between the inner sides of the column clips at both ends of the beam, with a tolerance of ±0.5mm. Standard lengths are 1372mm, 2591mm, 2743mm, 3048mm, 3658mm, 3810mm, 4200mm.

Common Sizes:

- 80×50×1.5

- 90×50×1.5

- 100×50×1.5

- 110×50×1.5

- 120×50×1.5

- 140×50×1.5

- 160×50×1.5

- 160×50×1.8

- 160×50×2.0

Safety Feature:

Beams 80×50 and 100×50 use 3-hook clips, load up to 3T per level. Beams 120×50 and above use 4-hook clips, load up to 4T per level. Consult technical support if load exceeds 4T per level.

| Beam Loading Capacity (Kgs) | ||||||||

| mm | 1372 | 2591 | 2743 | 3048 | 3658 | 3810 | 4200 | |

| Dimension | L/200 | L/200 | L/200 | L/250 | L/250 | L/300 | L/300 | |

| 80×50×1.5 | 3 Pins | 3,781 | 1,520 | 1,356 | 1,098 | 610 | 562 | 386 |

| 90×50×1.5 | 3 Pins | 4,000 | 1,853 | 1,654 | 1,339 | 744 | 686 | 470 |

| 100×50×1.5 | 3 Pins | 4,000 | 2,427 | 2,165 | 1,754 | 974 | 898 | 616 |

| 110×50×1.5 | 4 Pins | 4,000 | 2,748 | 2,559 | 2,073 | 1,151 | 1,061 | 728 |

| 120×50×1.5 | 4 Pins | 4,000 | 2,863 | 2,705 | 2,356 | 1,309 | 1,206 | 827 |

| 140×50×1.5 | 4 Pins | 4,000 | 3,340 | 3,155 | 2,839 | 1,781 | 1,642 | 1,126 |

| 160×50×1.5 | 4 Pins | 4,000 | 3,908 | 3,691 | 3,322 | 2,381 | 2,195 | 1,505 |

| 160×50×1.8 | 4 Pins | 4,000 | 4,000 | 4,000 | 3,898 | 2,794 | 2,576 | 1,766 |

| 160×50×2.0 | 4 Pins | 4,000 | 4,000 | 4,000 | 4,000 | 3,119 | 2,875 | 1,972 |

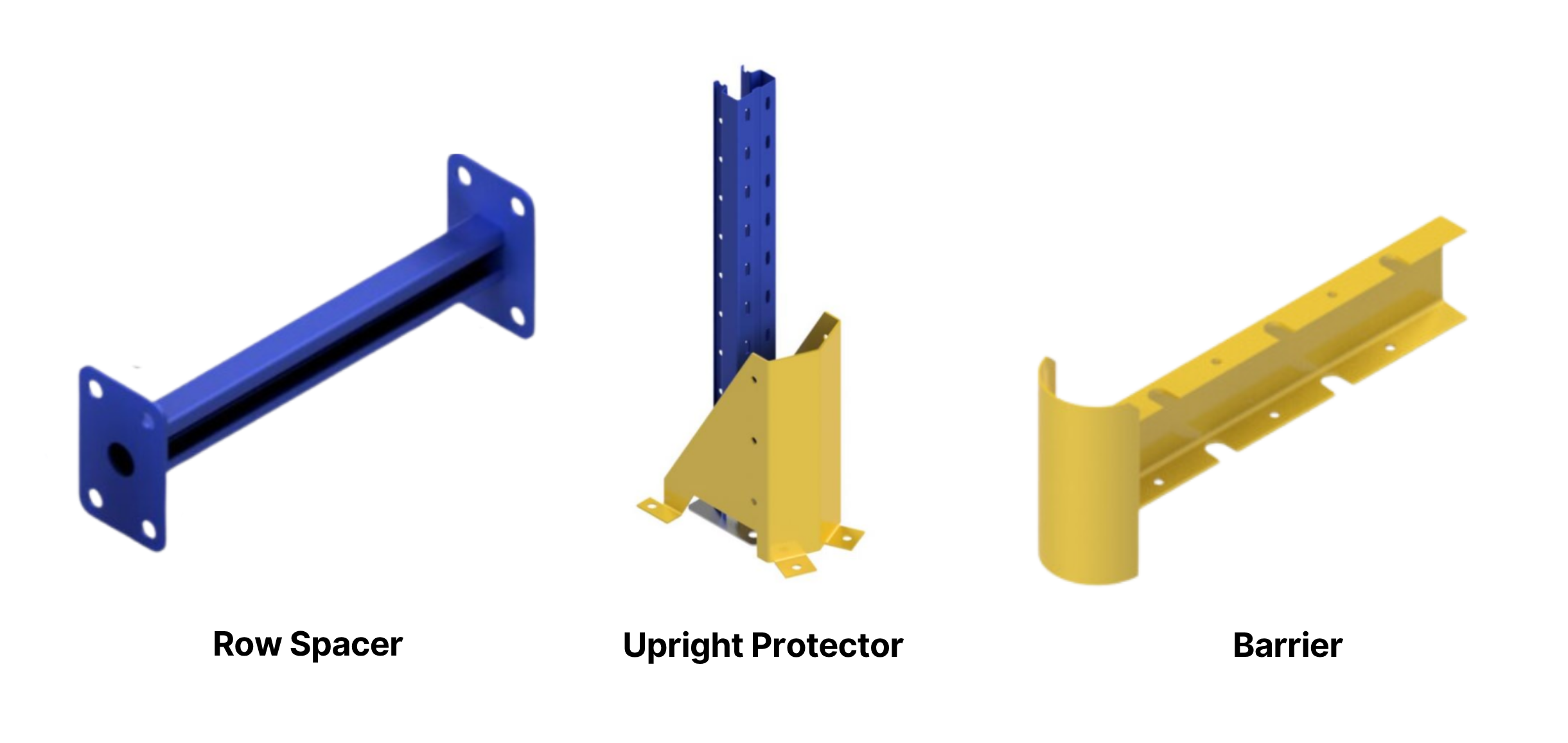

RACK ACCESSORIES

SYSTEM OPTIONS

- Height, Depth, and Width: Fully customizable based on warehouse layout and loading needs.

- Surface Finish: Standard powder-coated finish/Galvanized

PACKAGING & LOADING

Our packaging and loading process is meticulously designed to ensure each product arrives safe, secure, and ready for installation. Beyond protecting goods in transit, our professional packaging approach helps streamline operations – saving time and reducing the risk of damage during loading and unloading.

WHY CHOOSE BHD VIETNAM RACKING FACTORY?

- Experienced Manufacturer – Serving international markets with years of racking expertise.

- Global Reach – With factories in Vietnam and warehouses in the U.S. and Australia, we support fast and reliable shipments worldwide.

- Reliable Partner – We build long-term partnerships through dependable service, custom solutions, and consistent product quality.

- Export-Focused – We specialize in manufacturing for export, with a deep understanding of logistics, container optimization, and global compliance.

Other products

American Standard Teardrop Pallet Rack

Cantilever Rack

Wire Mesh Decking

60 Longspan Shelving